How To Close The Spark Plug Gap

In this article “How To Close The Spark Plug Gap” to guarantee ideal execution of your motor, it is urgent to consistently check the ongoing hole size of the flash fitting.

The hole size alludes to the distance between the middle anode and the ground cathode of the flash attachment.

A right hole size is fundamental for legitimate start of the air-fuel combination in the burning chamber.

Overlooking this perspective can prompt issues, for example, failing, unfortunate motor execution, and expanded fuel utilization.

To check the ongoing hole size, you will require a sensor measure. Basically embed the right thickness check between the anodes and tenderly change it until you feel slight obstruction.

Cautiously eliminate the check and measure the hole size demonstrated on it.

It is prescribed to counsel your motor’s manual to decide the particular hole size expected for your flash attachment.

By consistently checking and keeping up with the hole size, you can guarantee that your motor works productively and successfully.

Understanding the Significance of the Right Hole Size

The right hole size of a flash fitting is essential for the effective working of a motor. A flash fitting that has a mistaken hole size can prompt unfortunate motor execution, like discharge failures, unpleasant sitting, and diminished eco-friendliness.

This makes it fundamental for vehicle proprietors to consistently check and change the hole size on a case by case basis to guarantee their motor is running ideally.

A mistaken flash fitting hole size can likewise bring about troubles turning over the motor and a general decline in power.

This could not just influence the presentation of the vehicle at any point yet in addition lead to likely harm to other motor parts after some time.

By understanding the significance of keeping up with the right hole size of the flash fitting, vehicle proprietors can forestall exorbitant fixes and guarantee their motor is chugging along as expected.

Gathering the Vital Instruments and Materials

To appropriately change the hole size of a flash fitting, having the current important instruments and materials is fundamental.

Prior to starting the interaction, guarantee you have a hole measure explicitly intended for flash fittings.

This apparatus will permit you to precisely quantify and change the hole. Moreover “How To Close The Spark Plug Gap”, having a bunch of sensor checks will assist you with accomplishing the exact hole size expected for ideal motor execution.

Notwithstanding the devices, it is essential to have wellbeing hardware, for example, gloves and goggles to shield yourself from any likely risks while dealing with the motor.

Make a point to have a spotless fabric or cloth helpful to clear off any soil or flotsam and jetsam from the flash fitting before review.

By social affair these devices and materials in advance, you can smooth out the most common way of checking and changing the flash attachment hole actually.

Eliminating the Flash Fitting from the Motor

To start the method involved with eliminating the flash attachment from the motor, it is vital to initially guarantee that the motor is cool to the touch.

This will assist with forestalling any expected consumes or wounds during the expulsion interaction.

Utilizing the proper size attachment wrench or flash fitting attachment, cautiously slacken the flash attachment by turning it counterclockwise.

When the flash attachment is adequately slackened, it very well may be unscrewed the hard way and taken out from the motor.

Subsequent to eliminating the flash attachment from the motor, review it cautiously for any indications of harm or wear.

Search for signs, for example, fouling, consumption, or inordinate carbon stores, which might propose basic issues with the motor’s exhibition.

It is likewise a decent practice to contrast the eliminated flash fitting and another one to measure the degree of any wear or decay.

Appropriately discarding the old flash fitting and planning to introduce another one is the following stage in keeping up with the motor’s ideal presentation.

Estimating the Ongoing Hole Size

To quantify the ongoing hole size of a flash fitting, you will require a sensor measure.

This instrument comprises of a bunch of slim metal cutting edges of shifting thickness.

Start by choosing the suitable edge on the sensor check that matches the suggested hole size for your particular flash fitting model.

Embed the antenna measure between the middle anode and the establishing cathode of the flash fitting.

Delicately slide the edge this way and that to decide the hole size.

The sharp edge ought to fit cozily without being excessively close or excessively free.

Then, cautiously eliminate the antenna check from the flash attachment and observe the estimation showed on the sharp edge.

This estimation addresses the ongoing hole size of the flash fitting.

It is pivotal to guarantee that the hole size matches the maker’s details to keep up with ideal execution of the motor.

On the off chance that the deliberate size isn’t inside the suggested range “How To Close The Spark Plug Gap”, changes will be important to accomplish the right hole size for proficient flash fitting activity.

Changing the Hole Size

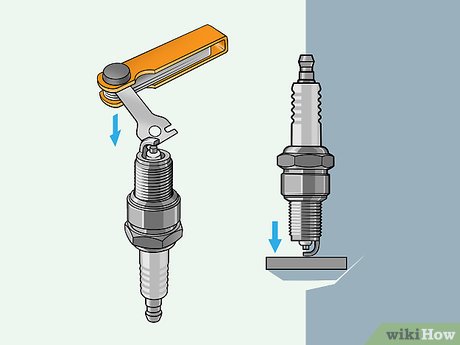

To change the flash fitting hole size, you should utilize a sensor check that matches the suggested estimation indicated by the maker.

Cautiously embed the sensor measure between the terminal and the ground anode of the flash attachment.

Tenderly twist the ground cathode either internal or outward to accomplish the right hole size demonstrated in the producer’s rules.

It is vital to deal with the terminals gently during this cycle to forestall any harm that could influence the flash attachment’s exhibition.

When the change is made, twofold check the hole size utilizing the antenna measure to guarantee it meets the necessary details.

Make any fundamental calibrating changes until the hole size is exactly lined up with the producer’s suggestions for ideal motor execution.

Guaranteeing the Hole Size is Right

In the wake of changing the hole size of the flash fitting, it is urgent to guarantee that it is right prior to reinstalling it into the motor.

An inaccurate hole size can prompt unfortunate motor execution “How To Close The Spark Plug Gap”, fizzles, and, surprisingly, possible harm to the motor parts.

To confirm the hole size, a sensor check ought to be utilized to gauge the distance between the middle terminal and the ground cathode of the flash fitting.

When the hole size has been estimated, it ought to match the maker’s details for the particular motor model.

In the event that the hole size isn’t inside the suggested range, changes ought to be made likewise.

Guaranteeing the right hole size will assist with advancing the flash fitting’s exhibition, prompting proficient burning and dependable motor activity.

Reinstalling the Flash Attachment into the Motor

When the flash attachment hole has been changed in accordance with the right size, the time has come to painstakingly reinstall the flash fitting once again into the motor.

Care ought to be taken to guarantee that the flash attachment is strung in by hand at first to forestall cross-stringing, which could prompt harm to the motor.

Utilizing a flash fitting attachment and a force wrench, the flash attachment ought to then be fixed to the maker’s prescribed force details to guarantee a legitimate seal and forestall any issues with the motor’s exhibition.

After the flash attachment has been safely affixed into place, the flash fitting wire or start loop can be reattached.

It is essential to ensure that the wire or curl is cozily associated with the flash attachment to guarantee legitimate start.

Whenever everything is reassembled “How To Close The Spark Plug Gap”, the motor can be begun and tried to guarantee that it is moving along as expected and effectively.

Following these means for reinstalling the flash fitting into the motor will assist with keeping up with the presentation and life span of the motor.

Testing the Motor to Guarantee Appropriate Working

When the flash attachment has been reinstalled into the motor and all fundamental parts have been appropriately gotten “How To Close The Spark Plug Gap”, the time has come to test the motor to guarantee legitimate working.

Turn over the motor and permit it to run for a couple of moments, making note of any uncommon sounds or vibrations.

Screen the motor’s presentation, including speed increase and standing by, to guarantee that it is moving along as expected and with practically no issues.

Moreover, investigate the exhaust discharges to guarantee that they are clear and liberated from any strange smoke or scents.

Focus on any advance notice lights on the dashboard that might show issues with the motor.

On the off chance that everything seems “How To Close The Spark Plug Gap”, by all accounts, to be chugging along as expected, the flash fitting substitution process has been fruitful, and your motor is all set.

Keep in mind, standard support of the flash attachment hole is fundamental to forestall future issues and keep up with the ideal exhibition of your motor.

Routinely Keeping up with the Flash Fitting Hole to Forestall Future Issues

To forestall expected issues from now on, it is pivotal to routinely keep up with the flash fitting hole of your motor.

Inability to keep the hole size inside the prescribed reach can prompt unfortunate motor execution, trouble turning over the motor, and, surprisingly, possible harm.

By finding opportunity to occasionally check and change the flash fitting hole”How To Close The Spark Plug Gap”, you can guarantee that your motor works at its ideal level.

Going to proactive lengths to keep up with the flash fitting hole can likewise broaden the general life expectancy of your motor.

Disregarding this basic upkeep undertaking could bring about expensive fixes or substitutions down the line.

By integrating flash attachment support into your normal motor consideration schedule, you can keep likely issues from emerging and keep your motor moving along as expected for quite a long time into the future.